Right from the start, our fully digital workflow ensures transparent processes. The focus is always on process optimization and minimizing waste. Our lean principles are applied to the processes as early as the project phase.

Quality assurance

Our integrated CAQ system includes the following modules:

- APQR / advance quality planning

- Test equipment management

- Supplier evaluation

- audit

- SPC statistical process control

- Incoming / outgoing goods

- FMEA

- Quality management analysis

- 3D CNC coordinate measuring machines

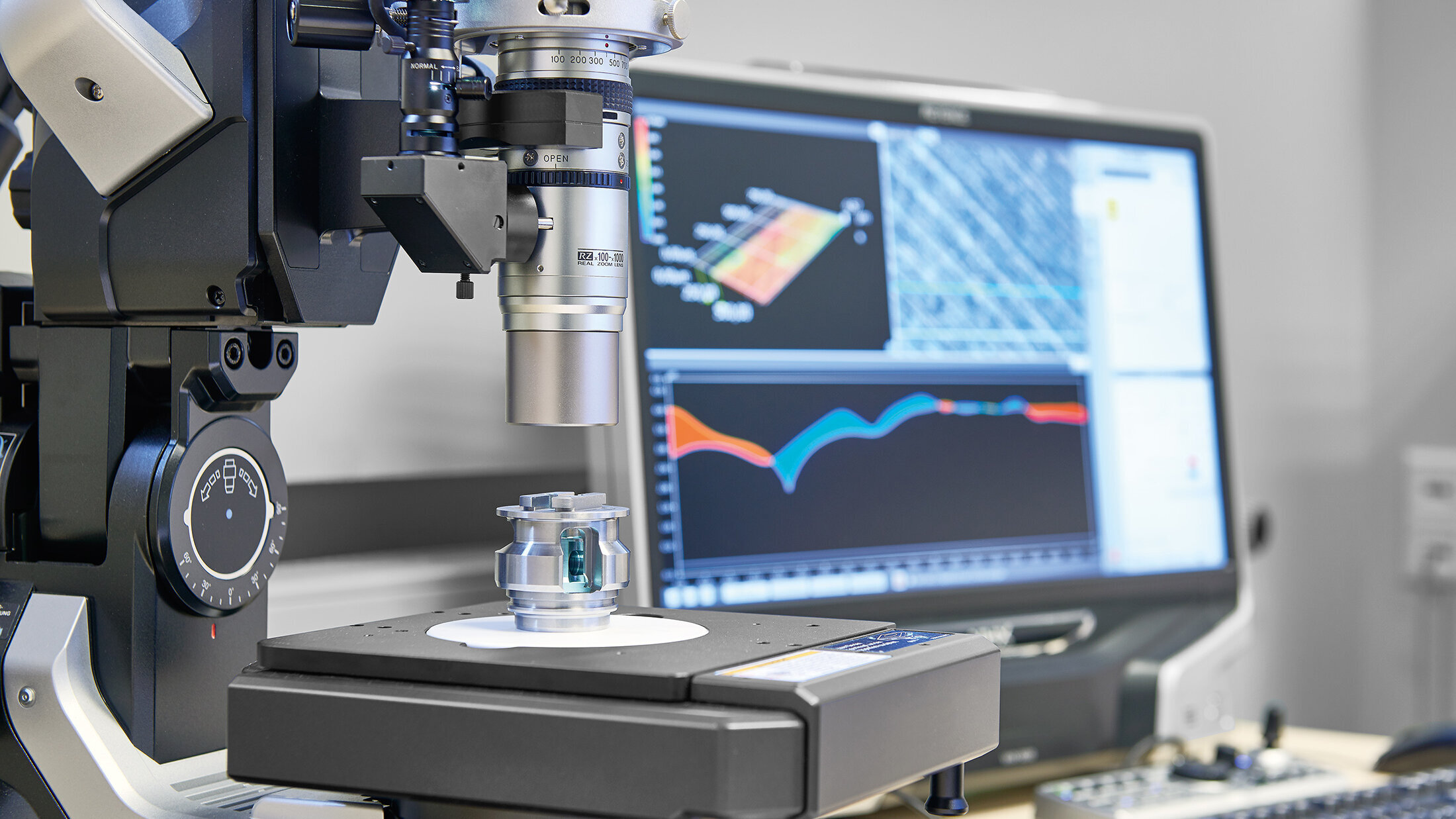

- Conturograph incl. roughness

- Measuring projector

- Coating thickness measurement

- Roughness testing

- Image processing and video analysis

- Endoscopy

- SPC test stations for production monitoring

- Scanning and optical measurement of external contours directly in production

- Endoscopy for the assessment of bore intersections

Shipping

Packaging and shipping also reflect our consistent quality awareness:

- Part-specific trays or blister packs and standard packaging materials

- Standard KLT containers in the exchange process

- Use of customer-specific packaging instructions and containers

- EDI transmission of shipping data - directly to customers or logistics service providers

Loops

Simple series parts (centerless) are ground by competent partners. Our specialty is round, non-circular and polygon grinding between centers. Several fits can be ground centrically and eccentrically in a single clamping operation. This allows tight shape and position tolerances to be maintained.

Material store

With raw materials of various qualities in stock, we guarantee "just in time" production.

The batch-managed bright steel warehouse with approx. 400 tons in stock offers high availability and therefore security of supply at all times.

If the diameter allows, each individual bar is provided with batch information.

Experience REES on a virtual tour of the company

Get to know us and our skills from a different perspective - namely from the inside: take our virtual tour of the company to see where we provide which services and how these stations are interlinked.

As you have already seen on the other pages: We have an exceptionally wide range of parts manufacturing capabilities, enabling us to produce sophisticated parts between 2 and 90 mm in diameter. Our turned parts can be found in ships, locomotives, trucks as well as in many cars and medical devices.

Our fast order processing, our high machine capacity and our reliable quality – just in time and just in frequency – make us a valued partner and often the A-supplier of our customers.